Writer:www.firemixer.com Time:2021-06-15 14:40 Browse:℃

What are the advantages of commercial jacketed kettle machine equipment used in factories?

Introduction:

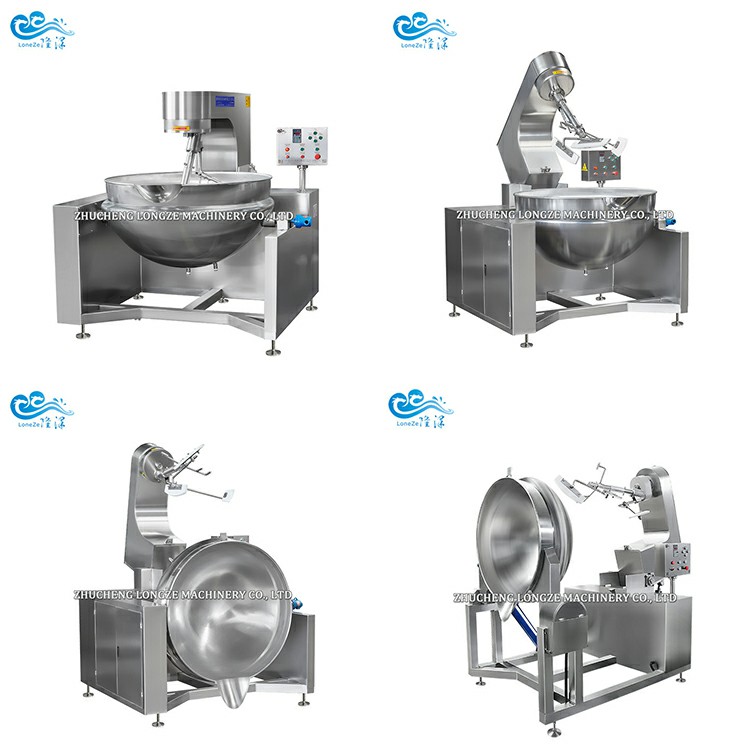

Jacketed kettle machine is usually composed of pot body and legs. The pot body is a double-layer structure composed of an inner and outer spherical pot body, and the middle layer is heated by steam. Commercial sandwich woks are available in fixed, tiltable, and stirring styles. Tilting jacketed kettle machine jacketed kettle machine has the characteristics of large heating area, high thermal efficiency, uniform heating, short liquid boiling time, easy control of heating temperature, beautiful appearance, easy installation, convenient operation, safety and reliability. The jacketed kettle machine is widely used in the processing of various foods, and can also be used in large restaurants or canteens to boil soup, cooking, stew, porridge, etc. How much is the jacketed kettle machine is a good equipment for food processing to improve quality, shorten time, and improve working conditions .

Fully automatic planetary jacketed kettle wok hydraulic tilting arm return system: The tilting arm return system uses a hydraulic station as the power source. When the hydraulic station is working, the output and input cylinders run smoothly, and there will be no stalls and jams like the cylinder. The motor of the hydraulic station is 2.2KW, and it is controlled and monitored by a safety travel switch when the arm is turned back to the arm. Multi-switch interconnection protection and control to avoid accidents and losses caused by operators' illegal operations. The factory uses commercial cooking jacketed kettle woks for discharging and turning, and the reboiler system uses a hydraulic station as the power source. When the hydraulic station is working, the output and input cylinders run smoothly, and there will be no stalls and jams like the cylinder. The motor of the hydraulic station is 2.2KW, and it is controlled and monitored by a safety travel switch when the arm is turned back to the arm. Multi-switch interconnection protection and control to avoid accidents and losses caused by operators' illegal operations.

Product structure and characteristics: The commercial cooking jacketed kettle wok is a double-layer structure consisting of an inner and outer spherical body, the middle layer is heated; the fixed type is mainly composed of the body and the supporting feet; the tilting sandwich wok is mainly composed of the body It is composed of a tiltable rack; a stirred jacketed kettle machine is mainly composed of a pot body and a stirring device.

1. This pot uses 220V electric power as the heat source, and has the characteristics of large heating area, high thermal efficiency, uniform heating, short boiling time of liquid, and easy control of heating temperature.

2. The pot body adopts a stainless steel pot body formed by one-step spinning, which ensures that the pot is flat and smooth, and does not deform or stick to the pot during high-temperature heating.

3. Advanced combustion system, gas combustion is more complete, energy saving, environmental protection, no need for smoke exhaust system.

4. Natural gas, liquefied gas, and biofuels can all be used.

5. Automatic temperature control, adjustable temperature, no sticking to the pot during use, no black smoke,

6. The temperature controller adopts full digital display, easy to operate, accurate control, and automatic control throughout the process.

7. The insulation layer is made of refractory cement, and the insulation effect is better. $)6MAJQUB)0~GYIS9S)(R76

Configuration:

1. Stirring method: frame-type wall scraping paddle, with directional choke paddle, power 0.75KW, speed 0-60 rpm, Delta frequency converter speed control, Siemens, Ousite reducer. Stirring paddle material: SUS304 stainless steel; scraper material: polytetrafluoroethylene.

2. Sealing form: mechanical seal.

3. How to open the cover: open the cover through the manhole.

4. Discharging method: discharging or pressing the material by the bottom valve.

5. Temperature display: thermal resistance thermometer (less than or equal to 140 degrees).

6. Vacuum degree: pressure vacuum gauge, vacuum gauge≦-0.09Mpa.

7. Heating and cooling method: jacket electric heating, tap water cooling.

8. Capacity design: Design volume is 130L, working volume is 100L.

9. The main process parameters: jacket working pressure 0.03MPa, inner pot working pressure -0.09-0.02MPa.

10. Material used: inner pot material SUS304 stainless steel, thickness 6mm, jacket material SUS304 stainless steel, thickness 6mm, shell material SUS304 stainless steel, thickness 3mm.

11. Upper pot cover: material: SUS304 stainless steel, thickness: 6mm, attached (vacuum pressure gauge, vent valve, vacuum port, mirror light, mirror port with scraper, manhole, spice funnel;).

12. Polishing grade: The inner and exposed parts of the pot are larger than 300 meshes.

13. Vacuum pump: water ring vacuum pump 0.55KW, select Zibo brand.

14. Heating method: electric heating, heating power 6KW*2 equal to 12KW, heating time of the whole pot is about 10 minutes.

15. It is recommended to choose an operating platform above 300L: with step stool, patterned non-slip aluminum plate

16. Jacket level display: magnetic flap level gauge

The mixing method is driven by a special horizontal reducer, and the agitator used is in full contact with the pot body to realize the transmission ratio of non-integer transmission, ensuring that there is no dead corner in the pot, and the material is evenly stirred and does not stick to the pot. The transmission part adopts advanced transmission and sealing structure to ensure the clean and hygienic inside of the pot.

Classification of cooking jacketed kettle woks:

1. The volume is divided into: 50L, 100L, 200L, 300L, 400L, 500L, 600L, 800L, 1000L. 2. The structure is divided into: tiltable and vertical structure.

3. The mixing is divided into: ordinary mixing, bottom scraping mixing, planetary mixing.

4. Heating method: electric heating, steam heating, gas heating.

5. Sealing method: no cover type, flat cover type.

6. Pot body material: ①Inner pot body stainless steel (SUS304), jacket, bracket; ②All stainless steel inside and outside (SUS304).

In modern society, the increasing progress of science and technology has promoted the improvement of the level of mechanization in all walks of life. For example, the food industry has transformed from pure labor operations in the past to semi-automated and fully automated mechanical operations. While the labor force was liberated, production efficiency has increased tremendously. This cannot but show the powerful force of technological development to promote productivity. The cooking jacketed kettle wok is not a leader in the field of food machinery, but you will be surprised by the various parameters of the commercial jacketed wok equipment. The ability of the cooking jacketed kettle wok is so great.

Classification of Longze Brand Commercial jacketed kettle machines:

1. According to the structure, it is divided into: vertical tilting jacketed kettle machine and (fixed) jacketed kettle machine structure.

2. According to the heating method, it is divided into: electric heating jacketed kettle machine, steam heating jacketed kettle machine, gas heating jacketed kettle machine, electromagnetic heating jacketed kettle machine.

3. According to the needs of the process, the equipment with stirring or without stirring is adopted.

4. According to the sealing method, the jacketed kettle machine can be divided into: no cover type, flat cover type and vacuum type.

Whatsapp/Wechat: +8615621793520

Phone: +8615621793520

qq: 3206879011

Email: Raymond@loneze.com

Add: No.215, Zhanqian Street, Zhucheng City, Weifang City, Shandong Province, China